Layout of the entire industry chain

Build a 100 billion-level all-vanadium liquid flow energy storage battery industry chain

All-vanadium liquid flow battery equipment and system working principle

Upstream raw materials

Flow Battery Materials

Application Areas

All-vanadium liquid flow battery equipment and system

All-vanadium redox flow battery - a pollution-free battery for energy storage

In 1985, the concept of all-vanadium liquid flow battery was first proposed. After 30 years of development, all-vanadium liquid flow battery has become one of the most suitable batteries for large-scale energy storage applications.

Product Center

Safe, environmentally friendly, and clean

1MW4MWh container energy storage system (power can be customized)

The 250kW energy storage system module is composed of 8 32kW stacks connected in series and parallel, and each module is equipped with a liquid storage tank and pipeline system. A MW-level energy storage system can be composed of multiple modules. For example, a 1MW4MWh all-vanadium liquid flow battery energy storage system can be composed of 4 250kW energy storage system modules.

Model

Power

Rated capacity

DC voltage range

AC output voltage

Maximum current AC

Energy efficiency

Communication interface & protocol

Response time

Insulation resistance

Container size L×D×H

Overall dimensions L×D×H

Installation space L×D×H

Total weight

Operating temperature range

Operating environment humidity

YFM2504H

250kW

1000kWh

324-460V

380V

500A

>75%

RS485,Modbus-RTU

100ms

>550MQ

7.689×2.438×2.896m

10×8.5×4m

12×10×4.5m

118t

-30℃-45℃

5%-95%

YFLO104H

1000kW

4000kWh

324-460V

380V

2000A

>70%

RS485,Modbus-RTU

100ms

>550MQ

7.689×2.438×2.896m

20×17×4m

24×20×4.5m

472t

-30℃-45℃

5%-95%

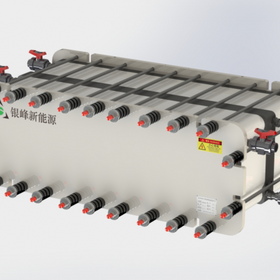

32KW battery stack

Parameter

Rated Power

Rated current

Energy efficiency

Dimensions

Stack weight

Unit

KW

A

%

L x H x D mm

Without liquid kg

Index

32

350

>80

1453X512X800

670

Battery Management System

The battery management system adopts a two-level architecture. The lower-level BMU is responsible for monitoring the stack voltage, stack current, relay control, circulation pump control, insulation monitoring, etc., and communicates with the upper-level BAMS; the upper-level BAMS is responsible for various sensor monitoring of the battery system, battery system balancing management, environmental system control, and communicates with the PCS and the smart microgrid comprehensive energy efficiency management platform. At the same time, a protocol conversion device is configured to match different protocol requirements.

Vanadium battery electrolyte

The vanadium electrolyte developed by the company has good electrochemical properties, and the metal impurity content is significantly better than the national standard first-class product. Its performance has been unanimously praised by domestic and foreign customers.

Parameter

Total vanadium concentration

Sulfate concentration

Average valence of vanadium

density

Unit

mol/L

mol/L

g/ml

Index

1.0 ~ 1.8

3.5 ~ 5.5

3.5

1.3-1.4

Product Features

China has abundant vanadium resources, ranking first in the world

The abundance of vanadium resources in the earth's crust is 160ppm, ranking 20th in the world, exceeding cubic feet per cubic foot. China's vanadium resource reserves rank first in the world.

Long cycle life

It can be frequently deeply discharged (100% DOD) and the charge and discharge cycle times can reach more than 16,000 times . The electrodes and electrolyte will not deteriorate due to the charge and discharge cycles and can be used for a long time.

High cost performance

High reliability and low operation and maintenance costs

Modular design, flexible layout

Power and capacity are independent, energy units and power units are customized

Fast charge and discharge response

Fast response time, less than 100 milliseconds, no need for “equalization” charging (overcharging the batteries to ensure all cells have the same charge)

Safety and environmental friendly

Closed operation at normal temperature and pressure, no risk of explosion or fire, excellent environmental friendliness

Production Base

Hunan Yinfeng New Energy Co., Ltd.

Hunan Yinfeng New Energy Co., Ltd., established in 2013, is a high-tech enterprise focusing on the research, development, manufacturing and commercial application of a new type of high-power and large-capacity energy storage product - all-vanadium liquid flow battery energy storage system.

The Changsha fuel cell stack and system integration production base provides products and technical services such as fuel cell stacks, battery management systems, energy storage modules, etc., carries out research and development of key battery materials, verification of new key materials and performance testing of new fuel cell stacks, and has an automated production line with an annual output of 50MW of fuel cell stacks.

Jiangxi Yinhui New Energy Co., Ltd.

Jiangxi Yinhui New Energy Co., Ltd. was established in March 2020 and is located in the Economic and Technological Development Zone of Yichun City, Jiangxi Province. It has a registered capital of RMB 100 million and a total planned land area of 300 acres. It is mainly engaged in the production and sales of high-purity vanadium and vanadium electrolyte.

The company has mature vanadium electrolyte preparation technology and battery-grade high-purity vanadium production process, and has built a vanadium electrolyte production base with an annual output of 66,000 cubic meters. The company has advanced production equipment, leading technology in the industry, and product quality that is superior to international standards. It has been widely used in the United States, Singapore, Morocco, South Korea and other domestic and foreign regions. The company is committed to becoming a leading enterprise with a vanadium resource industry chain that improves the quality and efficiency of vanadium resources from vanadium ore smelting to vanadium electrolyte production and then to vanadium recovery.

Jiangxi Yinfan New Materials Co., Ltd.

Jiangxi Yinfan New Materials Co., Ltd. was established in July 2024. It is located in Chaoxia Road, Pharmaceutical Industrial Park, Yuanzhou District, Yichun City, Jiangxi Province, with a registered capital of 100 million yuan. It focuses on the research and development and production of high-performance vanadium series products, including vanadium oxides (vanadium pentoxide, vanadium trioxide), vanadates (ammonium metavanadate, potassium metavanadate, etc.), etc. The company has advanced production facilities, high levels of engineering and automation, and is in a leading position in the world. It also has a complete sewage treatment system to achieve recycling.

The company adheres to the development concept of "industry focus" and is committed to deepening and refining the field of vanadium products, constantly improving its professional level and market position. Through continuous technological innovation, the company maintains its advantage of "technological leadership", promotes the application expansion of vanadium, and provides strong support for scientific and technological progress and industrial upgrading.

Implementation Examples

China National Energy Investment Group Co., Ltd.-Beijing Low Carbon and Clean Energy Research Institute

1 / NicerNet Distributed Multi-Energy Nanogrid System Smart Energy System Solution (5kW/25kWh)

-

The project integrates distributed new energy such as wind energy and solar energy; it integrates multiple energy storage forms such as liquid flow batteries, lithium-ion batteries, water electrolysis to produce hydrogen, high and low temperature hydrogen fuel cells, Jinzhan air batteries, and electric gas production.

-

Cooperating with the energy operating system, distributed communication is applied to realize the control, management and application of distributed energy, and the optimal configuration plan of each subsystem is calculated according to actual conditions. It has multiple functions such as smooth output, peak regulation, frequency regulation, backup power supply, demand-side response, etc., which can realize the testing, certification and development of various energy equipment under distributed microgrids.

-

The system architecture of energy system operation is divided into three layers: Cloud, Fog and MIST. The Cloud layer is the application layer, which realizes the analysis, processing and control of the energy data of the whole network; the Fog layer is the core of EOS, which is the hub for the interaction between the application layer and the driver layer to realize regional control; the MIST layer, as the driver layer of EOS, directly faces the equipment and realizes local energy control.

2 / Low Carbon Institute Flow Battery Energy Storage Technology Application Demonstration System Project (30kW/100kWh)

-

The Low Carbon Institute's flow battery energy storage technology application demonstration system consists of a 66kW photovoltaic power generation system, a 100kW energy storage inverter, and three 10kW33kWh all-vanadium flow battery energy storage systems.

-

The low-carbon institute's flow battery energy storage technology application demonstration system consists of a photovoltaic power generation system, energy storage inverter, all-vanadium flow battery energy storage module and management system, which can realize power supply solutions such as grid-connected electricity, peak-peak electricity use, and photovoltaic output power smoothing. The operation of the photovoltaic grid-connected energy storage system can realize various power metering and analysis of light and storage, obtain the charging and discharging energy operation data of the all-vanadium flow battery energy storage system, and provide data support for the application of the all-vanadium flow battery energy storage system in large-scale energy storage systems.

Shandong Hi-Speed New Energy Development Co., Ltd.

3 / Binlai Expressway Wenchang Lake Service Area All-vanadium Liquid Flow Battery New Energy Storage Project (250kW/1MWh)

-

In order to cope with the fluctuation of power load and unstable photovoltaic power generation in highway service areas, a 250kW/1MWh all-vanadium liquid flow energy storage system was designed. The system adopts a modular design, consisting of two 125kW/500kWh independent energy storage modules, integrating special container insulation and environmental intelligent control technology, with the advantages of high safety, long cycle life, and independent configuration of power and capacity. It has outstanding performance in the construction of zero-carbon service areas in terms of technology, economy, society and environment.

-

Each module contains 125kW containerized power units, liquid storage tanks, chillers and other auxiliary equipment. The 125kW power unit is connected through the DC side interface of the energy storage converter, and the output is connected to the 0.4kV power grid through the circuit breaker. The entire system is controlled by the energy management system (EMS) to achieve peak load regulation, frequency regulation, smooth output and reactive power compensation, ensuring the quality and stability of the power supply of the service area power grid.

Wencheng County Changtai Electric Power Co., Ltd.

4 / Research on the future form of distribution network technology of "hydrogen vanadium water and light charging intelligence" for future rural application scenarios

And demonstration project (80kw/240kWh)

-

In response to the problems of low power supply reliability and insufficient intelligence level at the end of the power grid in mountainous areas of my country, a future form distribution network and engineering demonstration project of "Hydrogen Vanadium Hydroelectric Solar Charging" was established for future rural application scenarios. The project utilizes the complementary characteristics of renewable energy and energy storage such as small hydropower, photovoltaics, all-vanadium liquid flow battery energy storage, green electricity to helium, and hydrogen-to-electricity conversion. It has built an 8kW/240kWh all-vanadium liquid flow energy storage system, constructed a "hydrogen vanadium hydroelectric solar charging" multi-energy complementary distribution network, realized intelligent control and dispatching of the distribution network, and absorbed 100% of renewable energy, helping to achieve the reliability, low carbonization and intelligence of future power supply in future villages, and meet the daily electricity needs of rural residents.

Shanghai Electric (Anhui) Energy Storage Technology Co., Ltd.

5 / Electrolyte supply for Shanghai Electric's all-vanadium liquid flow energy storage project

-

The vanadium electrolyte sold by the company to Shanghai Electric has been successfully applied to many large-scale energy storage projects due to its excellent performance and stability. For example, the Jiangsu Huadian Guanyun 200,000 kW/400,000 kW-hour energy storage project uses our vanadium electrolyte, which significantly improves the efficiency and safety of energy storage. Baotou Bailing Energy Storage's 5MW/20MWh grid-side all-vanadium liquid flow hybrid energy storage project also chose our products to achieve stable operation and efficient dispatching of the power grid. In addition, the Shantou Shanghai Electric Wind Farm 125KW/500KWh supporting energy storage project, the Xinjiang Aksu Energy Storage Power Station Phase I vanadium battery energy storage power station 1MW/4MWh and the Qinghai Yellow River Hydropower Company Wind Farm 1MW/4MWh supporting energy storage project all use the vanadium electrolyte sold by the company to Shanghai Electric, demonstrating the company's professional strength and wide application in the field of energy storage.

Huantai Energy Storage Technology Co., Ltd.

6 / Electrolyte supply for Huantai Energy Storage's all-vanadium liquid flow energy storage project

-

As the industry's leading vanadium electrolyte production and supplier, the company has been providing high-performance vanadium electrolyte products to multiple all-vanadium flow battery energy storage projects of Huantai Energy Storage, supporting the efficient implementation of customer projects with high-quality materials.

-

In the 15MW/60MWh all-vanadium liquid flow energy storage power station in Guazhou County, Jiuquan City, Gansu Province, our company supplies high-stability vanadium electrolyte for the project to ensure the long-term operation of the power station in the peak load regulation of the power grid and the grid connection of renewable energy; for the 2MW/12MWh user-side energy storage project in Wenzhou, Zhejiang Province, our vanadium electrolyte, with its long cycle life characteristics, helps the system achieve significant optimization of the electricity cost of industrial and commercial users. In addition, in the Guangzhou 500KW/2500KWh demonstration project and the Hebei Xingtai 10MW/40MWh energy storage power station and other projects, the company has supplied vanadium electrolyte on a large scale based on the needs of different scenarios, becoming a key link in the reliable supply chain of the Huantai energy storage project, providing solid material guarantees for the application of all-vanadium liquid flow battery technology in multiple scenarios, and promoting the high-quality development of the new energy storage industry.

.png)